Batteries in automotive applications must be continuously monitored to make sure that the battery is in a healthy state. A weak battery must be detected, and consumer loads should be deactivated if possible – especially, when the Start/Stop-feature is used extensively in city traffic, leading to heavy stress of the battery.

Health monitoring in the car includes continuous voltage-, temperature- and finally current measurement directly at the battery poles. Currents may reach several 100 Amps for various consumers and the starter-generator. Battery sensors must keep up with those high currents and must be tested accordingly. Accuracy of the sensor element must be proved by calibration during development, validation, and production.

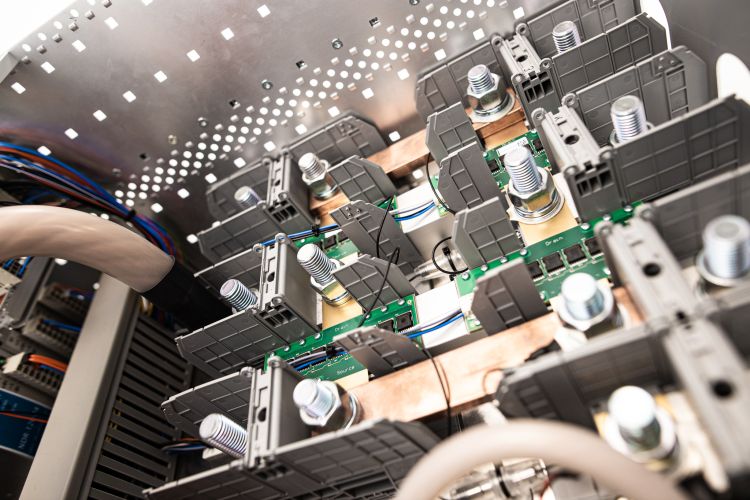

Thus, IRS provides a system to measure the applied current both for validation tests and calibration of the sensors. Both low currents in the range of 0,1A and very high currents up to 3kA can be validated precisely.

Key Facts

- Precise measurement equipment for test and calibration

- Measurement range +-3kA, 500A continuous current

- Voltage range 20V

- 1kS/s sample rate

- high accuracy @ 32-bit resolution.

- Dual range with automatic range selection

- Polarity reversal included