The media temperature control unit "IRS ICEcube PRO" is a powerful, versatile temperature control device for the precise temperature control of power electronic assemblies. It offers two independently controlled cooling circuits and is designed for demanding test bench applications – with minimal space requirements in the compact 19-inch format (12 U).

Technical Highlights

Two-circuit system for the parallel operation of two test subjects (50l/min per cooling circuit) or combined high flow.

High cooling performance: 15 kW at 10 K temperature difference.

Optional heating capacity: up to 15 kW.

Compact design: 19 inches, only 12 height units.

Flexible cooling medium: Water-glycol mixtures or fully deionized or desalinated water.

40 liters tank volume for stable regulation.

Technical Description

The unit impresses with its high nominal cooling capacity of 15 kW at a 10 Kelvin temperature difference between the test subject and mains water circuit, which is housed in the compact 19-inch format with 12 height units – ideal for applications with limited space and simultaneously high power requirements. For active temperature control, up to 15 kW heating power is also available on request.

Another technical highlight is the two cooling circuits within the only 12 height units high IRS ICEcube PRO, which enable the parallel operation of two test subjects. Both circuits feature a temperature- and flow-controlled feed. The flow controls of the two circuits operate independently of each other, and the temperature control acts across devices on the common tank volume of 40 liters. For applications requiring increased flow, the cooling circuits can also be operated in series. Flows of up to 100l/min are possible this way.

All common liquids can be considered as cooling media: Water-glycol mixtures as well as deionized water are equally suitable for the device.

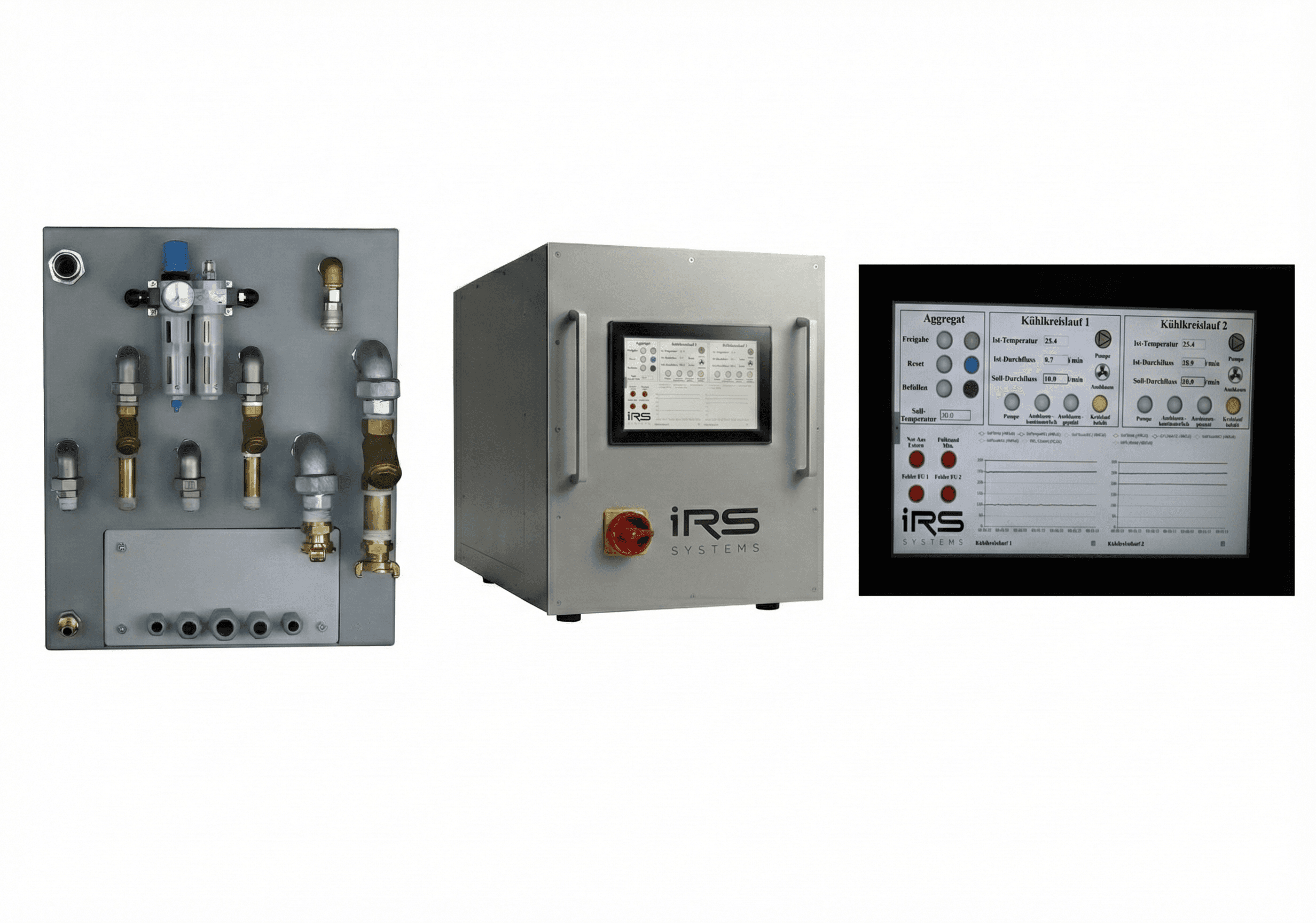

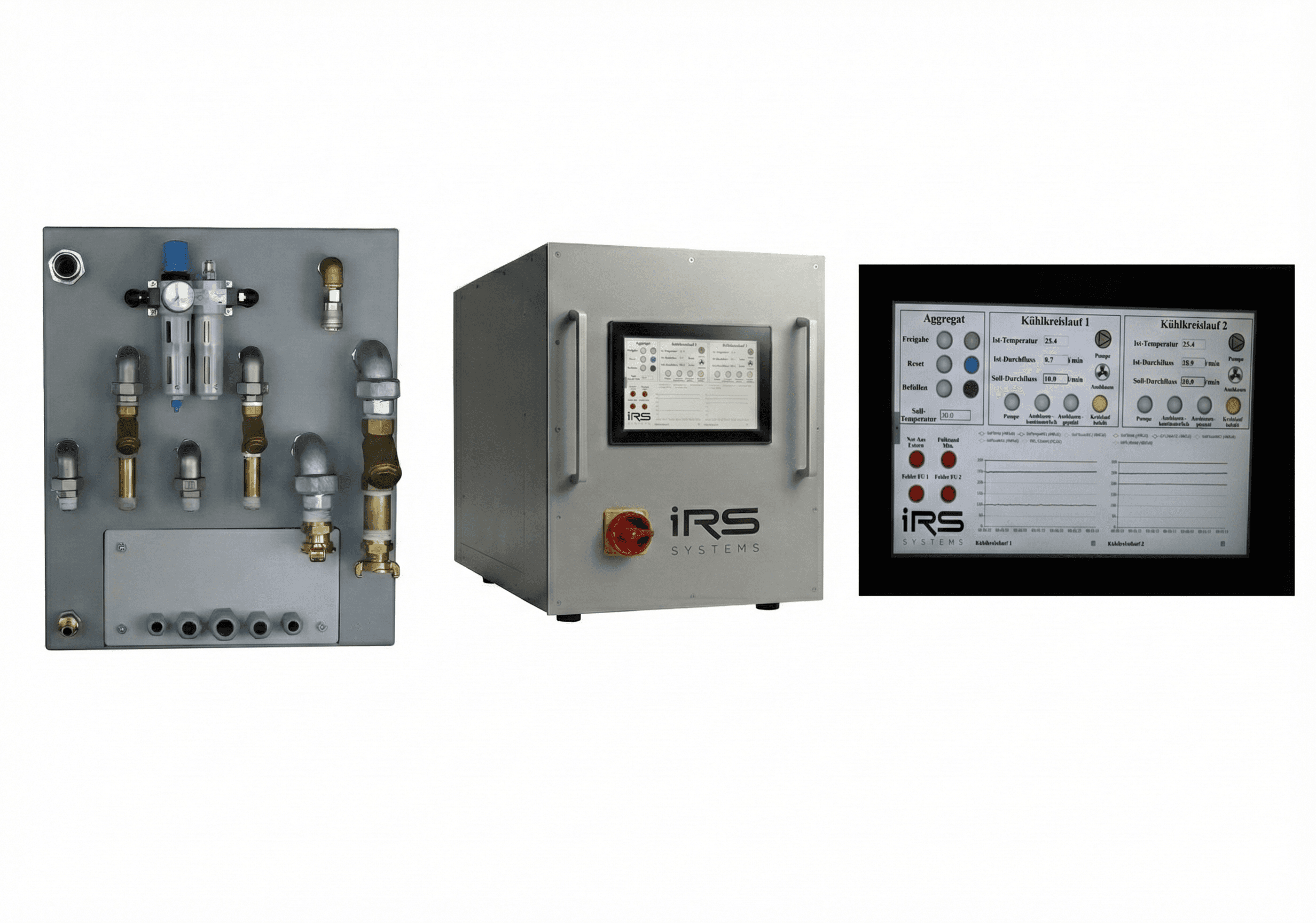

The system is equipped with a bidirectional blowing unit, allowing for a parameterizable emptying process – duration, direction, and pulsation can be individually adjusted. The blowing pressure can be precisely controlled via a manually adjustable compressed air maintenance unit.

Each cooling circuit uses robust peripheral pumps, which deliver depending on operating conditions up to 50 l/min flow per cooling circuit or alternatively up to 8 bar delivery pressure at 5 l/min flow – ideal for a wide range of testing requirements.

The control is either manual via a modern 10.1” touchscreen, or via a web interface. Alternatively, a comfortable remote control via the integrated Modbus/TCP or S7 interfaces is also possible. Optionally, the system is available with an external filling pump, which further simplifies handling.

The media temperature control unit "IRS ICEcube PRO" is a powerful, versatile temperature control device for the precise temperature control of power electronic assemblies. It offers two independently controlled cooling circuits and is designed for demanding test bench applications – with minimal space requirements in the compact 19-inch format (12 U).

Technical Highlights

Two-circuit system for the parallel operation of two test subjects (50l/min per cooling circuit) or combined high flow.

High cooling performance: 15 kW at 10 K temperature difference.

Optional heating capacity: up to 15 kW.

Compact design: 19 inches, only 12 height units.

Flexible cooling medium: Water-glycol mixtures or fully deionized or desalinated water.

40 liters tank volume for stable regulation.

Technical Description

The unit impresses with its high nominal cooling capacity of 15 kW at a 10 Kelvin temperature difference between the test subject and mains water circuit, which is housed in the compact 19-inch format with 12 height units – ideal for applications with limited space and simultaneously high power requirements. For active temperature control, up to 15 kW heating power is also available on request.

Another technical highlight is the two cooling circuits within the only 12 height units high IRS ICEcube PRO, which enable the parallel operation of two test subjects. Both circuits feature a temperature- and flow-controlled feed. The flow controls of the two circuits operate independently of each other, and the temperature control acts across devices on the common tank volume of 40 liters. For applications requiring increased flow, the cooling circuits can also be operated in series. Flows of up to 100l/min are possible this way.

All common liquids can be considered as cooling media: Water-glycol mixtures as well as deionized water are equally suitable for the device.

The system is equipped with a bidirectional blowing unit, allowing for a parameterizable emptying process – duration, direction, and pulsation can be individually adjusted. The blowing pressure can be precisely controlled via a manually adjustable compressed air maintenance unit.

Each cooling circuit uses robust peripheral pumps, which deliver depending on operating conditions up to 50 l/min flow per cooling circuit or alternatively up to 8 bar delivery pressure at 5 l/min flow – ideal for a wide range of testing requirements.

The control is either manual via a modern 10.1” touchscreen, or via a web interface. Alternatively, a comfortable remote control via the integrated Modbus/TCP or S7 interfaces is also possible. Optionally, the system is available with an external filling pump, which further simplifies handling.

Application Areas

Test stands for power electronics (e.g., inverters, e-motors)

Validation and end-of-line tests of drive inverters

Thermal stress tests with controlled cooling and heating functions

Research and development in the automotive sector, industrial electronics, aeromotive,…

Integration and Interfaces

Modbus/TCP for integration into test bench controls

Siemens S7 interface for connecting to a PLC

Web server for alternative operation and visualization

Optional additional interfaces by coordination

Application Areas

Test stands for power electronics (e.g., inverters, e-motors)

Validation and end-of-line tests of drive inverters

Thermal stress tests with controlled cooling and heating functions

Research and development in the automotive sector, industrial electronics, aeromotive,…

Integration and Interfaces

Modbus/TCP for integration into test bench controls

Siemens S7 interface for connecting to a PLC

Web server for alternative operation and visualization

Optional additional interfaces by coordination

IRS ICEcube PRO+

Optionally, a pH measurement and a conductivity measurement can be integrated into the storage tank. These functions allow for continuous monitoring of water quality and contribute to process safety as well as extending the lifespan of the cooling medium.

Note: The actual cooling performance strongly depends on the temperature difference between the incoming water and the test circuit. A rated power of 15 kW is typically achievable with a 10K temperature difference.